August 11, 2025

In October of 2023, via an effort led by the Akron Chamber of Commerce, the Akron area was recognized by the federal Economic Development Agency as a tech hub for bioplastics (more formally referred to as the Sustainable Polymers Tech Hub). This recognition was followed by a $51 million federal climate infrastructure investment in July of 2024, designed to scale up local efforts in bioplastics while making them better and safer, support workforce training for the next generation to participate in this industry, pilot test new bio-based products, and recover old tires for reuse.

In January of this year, Akron was also awarded another $3 million from the federal Commerce Department for its Good Jobs Challenge, in recognition of the value of building career pathways out of poverty into the new and growing bioplastics market.

The consumer demand for alternatives to single-use plastics and bio-degradable materials is growing fast, as well as the demand for green building materials made from renewable but nonbiodegradable “bio-feedstocks.”

Learn more about the region’s bioplastics manufacturing potential with our story map tool.

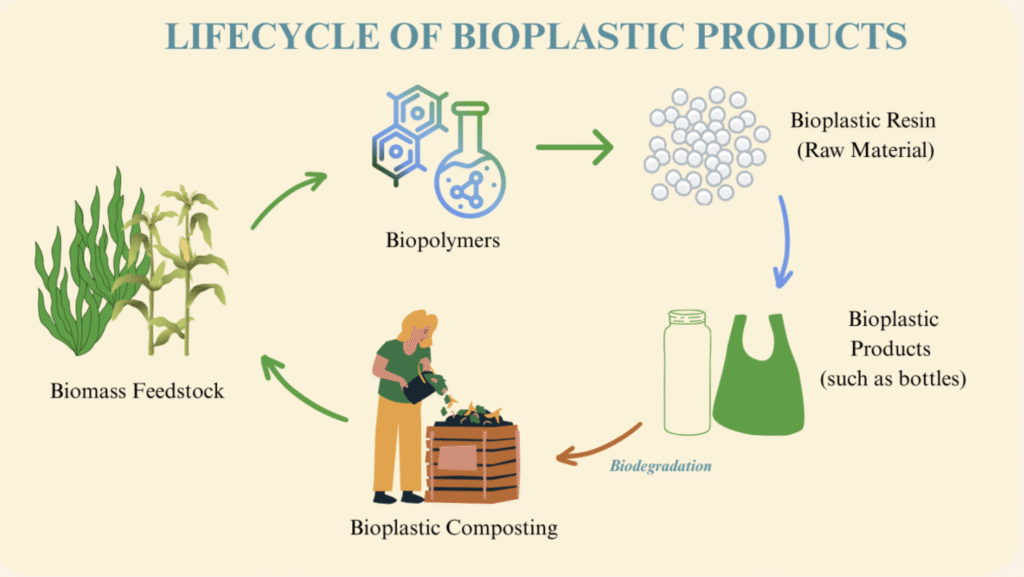

Lifecycle of bioplastic products. Image inspired by a diagram from the paper by Ali, S. et. al (2023).

A legacy of plastics manufacturing

Akron has long been the global leader in conventional plastics. With the right federal resources, it can now become a leader of the next generation of plastics – alternatives to single-use plastics made from biodegradable materials. In the process, via urban-rural partnerships, Akron can also bring along surrounding Appalachian communities to prosper under the development of a regional bioplastic supply chain.

Akron and Appalachia’s historic strength in both the plastics and building materials industries makes the region a prime candidate for the next generation of these fast-growing industries. For the Appalachian economy, it also represents a twofer—we can not only help make it in Appalachia, we can grow it in Appalachia, too. Win-win.

Read our recent report on the region’s economic potential in industrial hemp and bioplastics manufacturing here.

Economic analysts for the ReImagine Appalachia coalition recently looked more closely at the bioplastics industry, given the region’s historic strengths in plastics. They found that biodegradable plastics are increasingly being used for snack and other food packaging, beverage products, plastic cutlery, and restaurant to-go boxes. Bio-based materials are also being used in medical and pharmacy supplies, farm goods, textiles, and automotive parts. As bio-based feedstock made from crops can naturally regenerate, and hence is renewable, diversifying into bioplastics could make the existing industry in the Ohio River Valley region, which employs almost 40,000 people, more sustainable over the long haul.

The market is leaning towards a bioplastic future despite political disparaging

Federal climate infrastructure funds from the last federal administration have been helping to turn that vision into a reality. The new administration and Congress’ attack on federal climate resources is now putting at risk efforts to help the region’s industries thrive in the modern era, as global markets increasingly demand more sustainable products, in jeopardy.

We thank Representative Emilia Sykes for her leadership towards making Ohio a home for the future of manufacturing. We hope that Ohio Senators Moreno and Husted will also act to protect these funding streams. Now is not the time to pull the proverbial rug out from under these recent efforts by eliminating these federal climate resources. Now is the time to double down on them.

Market forecasts indicate robust growth for bioplastics in the United States, driven by this consumer demand. However, there are many challenges to establishing a robust domestic supply chain. A problem common to many would-be biofeedstock crops, for instance, is a lack of processing facilities suited to the specific part of the plant to be used as a feedstock for manufacturing. With hemp, for example, a major problem is a lack of processors for the hemp fiber.

This is how the chicken-or-egg problem gets solved: Farmers must gain assurance that there is a place where their crop can be processed after harvest and reliable buyers for their harvest. Manufacturers must have a reliable supply of the biofeedstocks used in their products. The processing facility is the middle piece that connects the farmers with the manufacturers, and it must function at scale within the region to nurture a stable biomaterials industry.

A decision to make

The Ohio River Valley region of Appalachia, including the Appalachian region of Ohio as well as West Virginia, Appalachian Kentucky, and Southwestern Pennsylvania, more commonly known as coal country, sits with its neighbors in the Akron area at a crossroads between the declining industries of the past and the rising industries of the future. In order to create lasting prosperity in a region that has long borne the brunt of boom and bust industries, new opportunities like this must be embraced. Ongoing federal investments in climate change will be necessary.

We can’t stop now.